Maintenance of car drive shaft

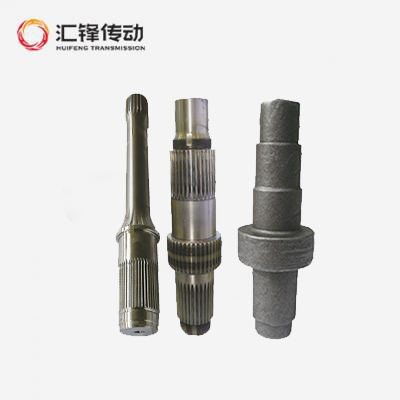

The transmission shaft is the shaft that can be transmitted when the universal joint transmission is transmitted. It is a rotating body with high speed and few supports, so its dynamic balance is very important. Generally speaking, the transmission shaft should be balanced and tested before leaving the factory, and adjusted on the balancing machine. For a car with a front-engine rear-wheel drive, it transmits the rotation of the transmission to the shaft of the final drive. It can be several parts, and the joints can be connected by universal joints.

During the running of the car, if the transmission shaft makes a continuous "whining" sound, first check whether the fastening bolts of the rubber gasket of the intermediate support bearing bracket are too tight or too loose, causing the position of the bearing bracket to deviate. The tightness of the bearing cover bolts can be adjusted to eliminate abnormal noise faults. If there is still noise after adjusting the bearing preload, check the lubrication of the bearing. If the bearing is poorly lubricated, the bearing should be disassembled for inspection and cleaning, and grease should be added before installing the composite bearing and bracket.

Use and maintain drive shafts

In order to ensure the normal operation of the transmission shaft,

To prolong its service life, attention should be paid to:

1. It is strictly forbidden to use a high-speed car to start.

Do not lift the clutch pedal violently.

Car overloading and speeding are prohibited.

The working condition of the drive shaft should be checked frequently.

Always check the fastening of the transmission shaft hanger, whether the supporting rubber is damaged, whether the connection parts of the transmission shaft are loose, and whether the transmission shaft is deformed.

6. In order to ensure the dynamic balance of the transmission shaft, we should always pay attention to whether the balance soldering piece is desoldered. The new driveshaft assembly is supplied by Supporting Equipment. When loading a new drive shaft, attention should be paid to the assembly mark of the telescopic sleeve to ensure that the flange fork is in a plane. When repairing and disassembling the transmission shaft, the assembly mark should be printed on the telescopic sleeve and the flange shaft to keep the original assembly relationship unchanged during reassembly.

7. The cross bearing of the universal joint should be injected with grease frequently. In summer, it should be injected with No. 3 lithium-based grease, and in winter, it should be injected with No. 2 lithium-based grease.